Stem cell therapy for regenerating intervertebral discs

Ulm’s simulator has Europe’s back

Back pain is often caused by intervertebral disc disorders. Much has already been tried and is available to help patients. Despite extensive progress, there is still no surefire recipe for success. iPSpine, an EU-funded project to which researchers from Ulm are contributing interdisciplinary engineering and biomedical expertise, aims to design a novel therapy for back pain based on intervertebral disc regeneration.

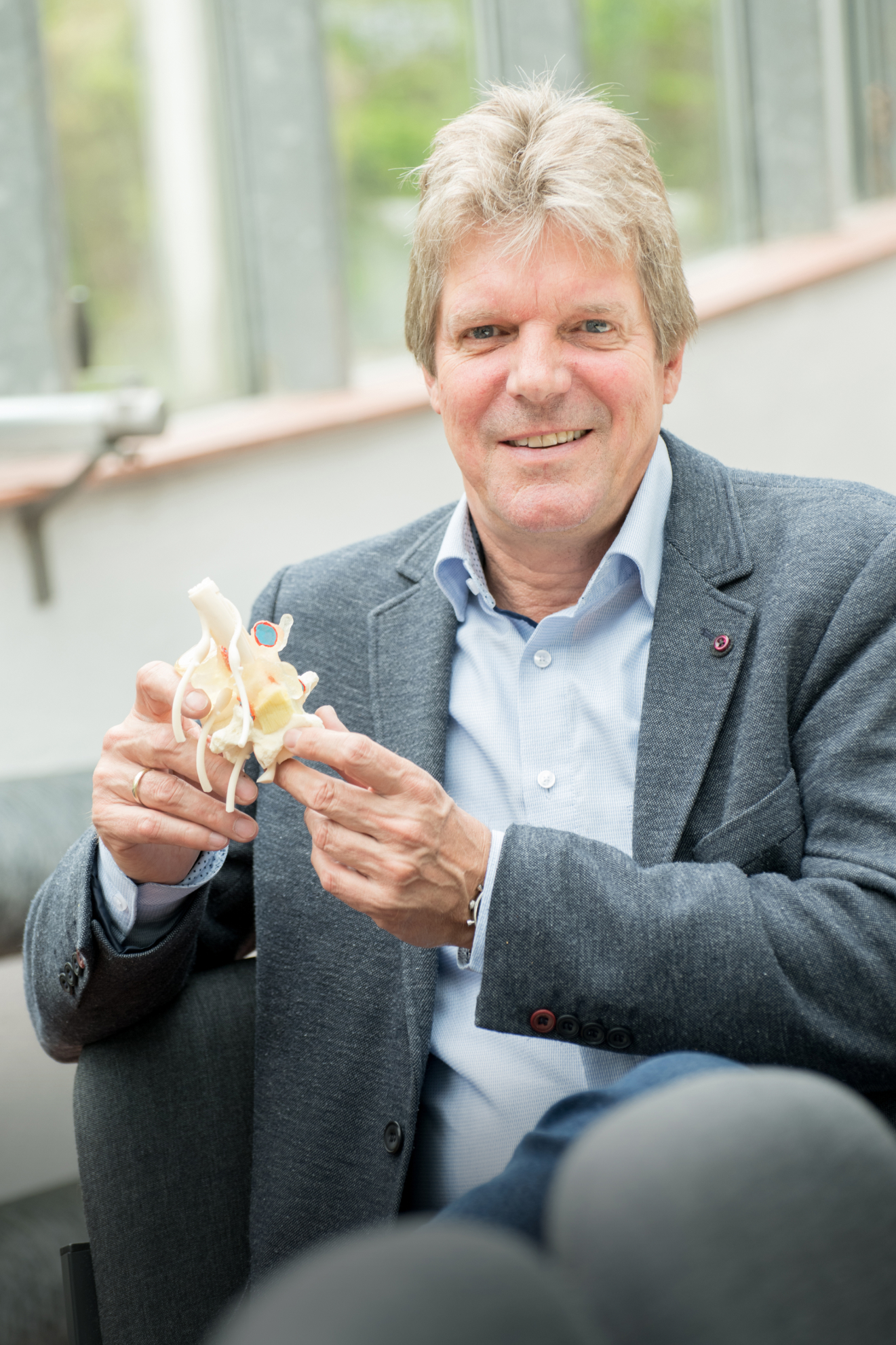

Prof. Dr. Hans-Joachim Wilke, who leads the project of the project partners in Ulm, with a vertebra model. © Elvira Eberhardt, Uni Ulm

Prof. Dr. Hans-Joachim Wilke, who leads the project of the project partners in Ulm, with a vertebra model. © Elvira Eberhardt, Uni UlmMusculoskeletal diseases top the list of causes of chronic diseases worldwide. Back pain is one of the most common complaints. Health surveys in Germany (GEDA 2009 and 2010) showed that around 25% of women and 16% of men suffered back pain that lasted for three months or more and occurred almost daily within a given year. This not only affects the health of individuals, but also of the economy and welfare systems due to sick leave and early retirement. The 23 intervertebral discs in the human body are at the centre of the disease. If they degenerate, the consequence can be painful herniated discs that require treatment. Gelatinous substance emerges from the gelatinous nucleus through the fibrous cartilage ring of the intervertebral disc and can press against the nerve roots along the spine. Therapy options for degenerated intervertebral discs range from pain relievers to physiotherapy and various surgical interventions.

In a major international project called iPSpine, launched in January 2019 with 15 million euros of EU funding, 20 project partners have been developing a novel therapy for regenerating intervertebral discs. The project aims to combine iPS (induced pluripotent stem cells) with biomaterials. The combination of iPS and biomaterials is expected to breathe life into degenerated intervertebral discs. The biomaterial will initially mechanically stabilise the disc and create a regeneration-friendly environment. The patient's own stem cells, for example from the blood, will be reprogrammed into iPS in the laboratory and returned to the patient. Basically, these stem cells can be differentiated into cells of almost any tissue. In this particular case, intervertebral disc precursor cells will be developed from iPS and then injected into the intervertebral disc together with the biomaterial. If everything goes to plan, the cells will then establish and multiply in the disc and form all the extracellular substances that a healthy intervertebral disc requires. So much for the theory. The project partners still have a lot of work ahead of them and numerous hurdles to overcome before practical implementation becomes possible.

Ulm’s task: authentic simulations

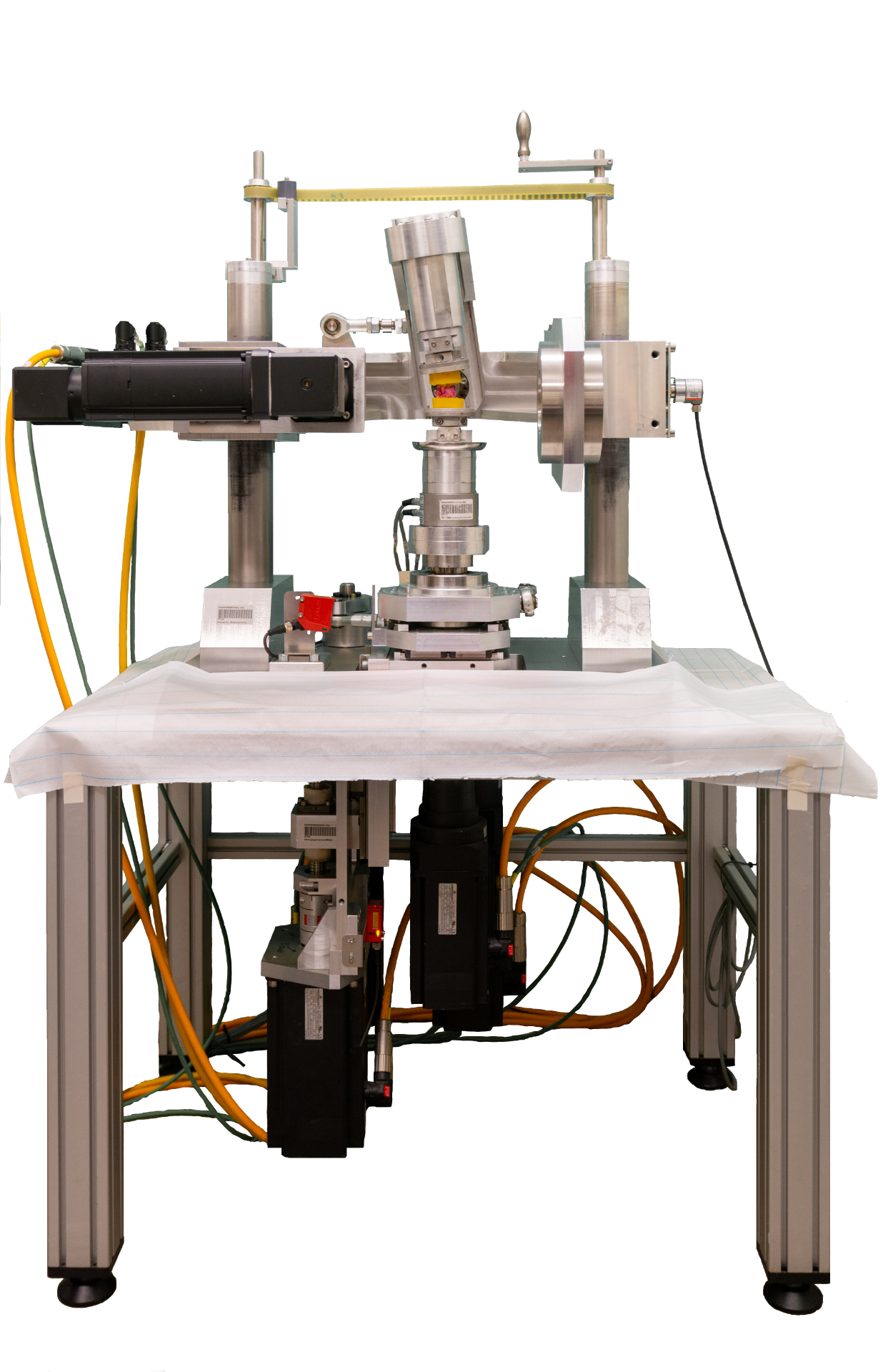

Using the dynamic variant of the spinal load simulator, spine movements, for example when hitting a golf ball, can be simulated in high frequency up to 5 Hertz. It takes just a few hours to analyse the consequences for the spine or intervertebral disc of someone’s movements in real life over a period of 5 to 10 years. © Hans-Joachim Wilke

Using the dynamic variant of the spinal load simulator, spine movements, for example when hitting a golf ball, can be simulated in high frequency up to 5 Hertz. It takes just a few hours to analyse the consequences for the spine or intervertebral disc of someone’s movements in real life over a period of 5 to 10 years. © Hans-Joachim WilkeA tool that is absolutely central to the project is being created jointly by two project partners in Ulm that have received around one million euros of EU funding. At the Institute of Orthopaedic Research and Biomechanics at the University of Ulm, a working group headed by Prof. Dr. Hans-Joachim Wilke, who is also a member of SpineServ’s scientific advisory board, has been dealing with the biomechanics of the spine for 30 years. Among many other achievements, his laboratory has developed special test methods for new surgical procedures and innovative implants for the spine, which are now used worldwide. The spin-off company SpineServ has been offering certified services to industry since 2007 and further develops them - as they are doing in this project - in cooperation with the university's researchers. "We can simulate physiological strain so realistically that we can reliably predict how the implant will behave in the human body," says Wilke. Turning, bending and lifting movements are no problem for the steel and aluminum construction of the electrically operated simulator. Shock and shear loads can be tested using real specimens and models. The Ulm simulator can also be used to examine the effectiveness of measures such as stiffening.

As part of the EU project, Wilke and his team are also using the spinal load simulator to test biomaterials developed by other project partners in real intervertebral disc preparations. "We use preparations from body donors and animals. The intervertebral discs of calf tails, which we obtain directly from the slaughterhouse, can now be kept alive for up to three weeks," explains Wilke. This gives the researchers and their partners enough time to artificially induce disc disorders for iPSpine and to try out the new therapeutic approaches. "We can cause inflammation with pinpricks or mechanical overload, and then determine the extent of the inflammation with the help of inflammatory markers such as interleukin. Or we use the enzyme chymopapain to cleave the peptide bonds in the proteoglycans of the gelatinous nucleus. In this way we can simulate a degenerated intervertebral disc," says Wilke.

The advantage of using chymopapain is that a hole is created in the intervertebral disc into which the biomaterial to be tested can simply be injected. However, the hole does not quite correspond to the real conditions of a degenerated intervertebral disc, because degenerated intervertebral discs have fissures rather than cavities. This is why the researchers are still experimenting with other enzymes. This work is being carried out in parallel with cell cultures produced by the Swiss cooperation partner, AO Research Institute Davos (ARI). "Our ambition is to develop a fissure model that is as authentic as possible," says Wilke. With the knowledge of the many, highly complex morphological changes in a real degenerated intervertebral disc, Wilke and his colleagues are convinced that the fissure model can only ever be a model and is therefore a compromise, although the best possible one available to date.

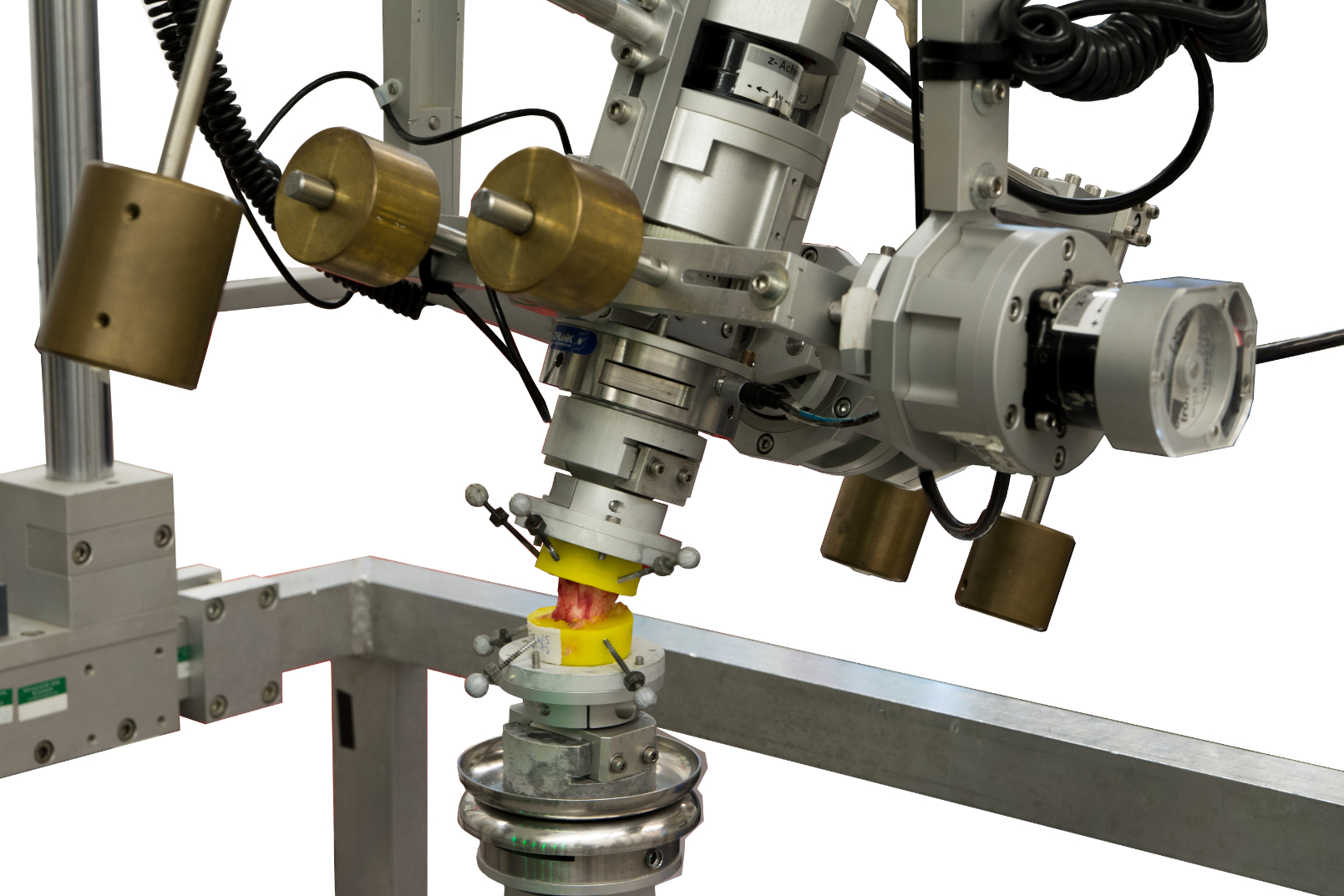

The Ulm simulator can even analyse slow movements with high precision. An infrared camera system is connected to the spinal specimen, and the camera’s sensors react to markers on the specimen. The system delivers kinematic analyses that are accurate down to the ten nanometre range. © Hans-Joachim Wilke

The Ulm simulator can even analyse slow movements with high precision. An infrared camera system is connected to the spinal specimen, and the camera’s sensors react to markers on the specimen. The system delivers kinematic analyses that are accurate down to the ten nanometre range. © Hans-Joachim WilkeARI’s project partners also cultivate iPS cells and investigate the interaction between the cells and the biomaterial. It remains to be seen which biomaterials are best. The researchers are currently working with hydrogels and albumin gels obtained from different research institutions and companies in Ireland and Germany, Wilke reveals. The intervertebral disc preparations are then clamped into the test bench of the Ulm research partners, and tested with or without biomaterials or cells. The intervertebral disc is either clamped into the system together with vertebral bodies framing it at its top and bottom or cast in plastic and thereby fixed. As far as biomechanical tests are concerned, the team uses various protocols to test all possible scenarios, over short and long durations, and with highly complex load conditions.

SpineServ is developing a special software for the project so that all effects can be measured, both degenerative and later regenerative effects, with the highest possible accuracy. According to Wilke, the Ulm-based company has hired experts for this specific task who will also incorporate artificial intelligence building blocks. Using iterative process control, these building blocks provide an even more precise database. Wilke hopes that "these software developments will become a new mainstay of the company and offer prospects for further services".

A travel-size simulator– for humans and animals

Doctoral student Laura Zengerle uses a plastic model to demonstrate how the spinal stress simulator works. © Elvira Eberhardt, Uni Ulm

Doctoral student Laura Zengerle uses a plastic model to demonstrate how the spinal stress simulator works. © Elvira Eberhardt, Uni UlmThe iPSpine project is being coordinated by Dr. Marianna Tryfonidou, Professor of Regenerative Orthopaedics at the Faculty of Veterinary Medicine at the University of Utrecht, and involves numerous groups from all over the world. To ensure that the cooperation partners all have easy access to biomechanical tests, the Ulm researchers are developing a mobile version of their spinal load simulator. At around one metre high, one metre wide and one metre deep it is easy to transport. Appropriately trained engineers can travel to the research partners. The big advantage is that this does not require the preparations, which are often very sensitive or less durable, to be sent around the world. "I developed the first spinal load simulator as part of my doctoral thesis. Since then, it has been continuously optimised for 25 years. I don’t think we will ever finish the simulator. It is constantly changing, and is now even being turned into a mobile version," says Wilke. As part of the EU-funded project, the simulator will also be adapted for animal preparations. The novel therapy is extremely interesting not only for human medicine, but also for veterinary medicine. Some dog breeds such as dachshunds are particularly susceptible to back problems and herniated discs due to their long body. If everything goes to plan, dachshunds will also be the first patients on which the new therapy will be tested.