Calling for quality seal for implants

Today's seniors are older and more active, which is why implants remain in the body longer and are subjected to greater strain than before. Improved surfaces are expected to ensure that the implants heal and integrate into the bone optimally. In an interview with BIOPRO, Dietmar Schaffarczyk, CEO of Konstanz-based stimOS GmbH, explains why a voluntary quality seal makes sense and gives consumers a better chance of recognising high-quality and safe implants.

You have written a position paper with other authors calling for more transparency as regards implants1. As a developer of implant surfaces, what motivated you to do this?

All patients should be able to rely on receiving the best implant possible based on the current state of technology. This should be standard practice for every implant manufacturer. For example, if an implant is subject to wear and tear, manufacturers should not be sweeping these undesirable effects under the carpet. A transparent quality seal would be beneficial for doctors and patients alike. However, such a seal would be voluntary for manufacturers. To this end, researchers, clinicians and a material manufacturer, working with a certification body, of which I am also an auditor, have developed a uniform evaluation procedure.

In Europe, implants need a CE mark before they are placed on the market. So why is there an additional need for a quality seal?

The CE mark means that a medical device as a whole complies with EU health, safety and environmental protection directives and regulations. However, it does not necessarily say anything about the quality standard of the individual components that make up an implant.

What difficulties does this pose for doctors who are spoilt for choice when it comes to implants?

It all starts with the fact that the term ‘coating’ is vaguely defined. We need to be able to distinguish between a coated surface, a modified surface or a composite material in order to assess the quality of an implant. Modified, for example, refers to the fact that the original implant material has been altered. One issue related to coating is material abrasion, where the material can make its way around the body and settle in the organs. As a patient, I would want to know that beforehand.

Isn't it enough that implants are tested for safety and efficacy before they are approved?

Sure, these tests are mandatory, but there are not always clear specifications on how to perform tests on individual components. It's like comparing apples and oranges. For example, did I perform the test with bone cells or with skin cells? Did I count the cells before or after rinsing the implant surface, because I wanted to detect the highest possible cell count? It also makes a difference whether I carefully insert the implant into a long bone in an animal test or force it into a dense bone like the iliac crest to deliberately provoke abrasion because I want to know how stable the coating is. Once the implant has been given marketing authorisation, I can no longer reconstruct all this.

How can a quality seal help consumers judge the quality of an implant?

Our first development was an evaluation matrix for surface functionalisations, where we basically demonstrate a level of evidence for evaluating the safety and performance of implants - the Safety and Performance Evidence Level (S.P.E.L.).2 If I had a quality seal with an evidence level of 80 to 100 percent, I would know that the manufacturers have tested their implants under the most realistic conditions possible and not in an ideal test environment. Below 50 percentage points, an implant manufacturer will probably think twice before attaching a voluntary quality seal to the implant packaging. But then, as a responsible patient, I can also decide on whether to use the implant from this particular manufacturer.

Which categories are included in this evaluation matrix?

For coatings or surface modifications of implants, we have initially identified six categories. We may also need to look at more aspects. That is why we have published open source so that manufacturers can continue to contribute. First, we check whether a company has introduced a certified quality management system before developing the implant. Then we check whether the implant surface has been produced in a GLP (good laboratory practice) certified laboratory with validated processes that reliably delivers the same results at all times. In the case of preclinical tests, one of the questions asked is whether the manufacturer or a neutral, accredited laboratory has performed the tests and whether the implants have been tested under real conditions. Last but not least, full points are awarded for handling if the surface applied does not change the implant's shelf life and sterilisability and does not complicate the operation.

This means that rather than evaluating test results, you evaluate how well the implant was manufactured and tested. Does the quality seal therefore supplement the CE mark?

Exactly, that’s what it does. CE marking and clinical trials, which are prerequisites for medical devices that are to be placed on the market, confirm that the implant is efficient and meets valid safety and health requirements. But as a patient, you won't be able to see the technical documentation. That is self-evident because technical documents contain a lot of company knowledge, such as formulations or procedures, some of which are subject to patent protection. Only the certification authority, the supervisory authority and possibly distribution partners have access to this information. The quality seal on the product packaging, on the other hand, enables the patient to conclude that individual components of the implant have been tested under real conditions. This is also a distinction for the companies that have been awarded the quality seal. However, our transparency strategy goes further than just a quality seal on the product packaging.

What else does it involve?

We also require a short, downloadable summary on the company website. This summary can be prepared in such a way that any interested layperson can understand which tests have been performed, why they were done, and what the results were. The download link can be printed on the product packaging along with the quality seal.

Who could issue this quality seal in the future?

This should not be a seal that companies can issue themselves. I envisage a neutral body that is already authorised to examine quality management or product data in the medical sector. This could be an existing certification authority or a Notified Body that already checks the product file before granting CE certification. On the basis of these data, the appointed body can also assess the level of evidence and then issue the quality seal that shows the level of evidence.

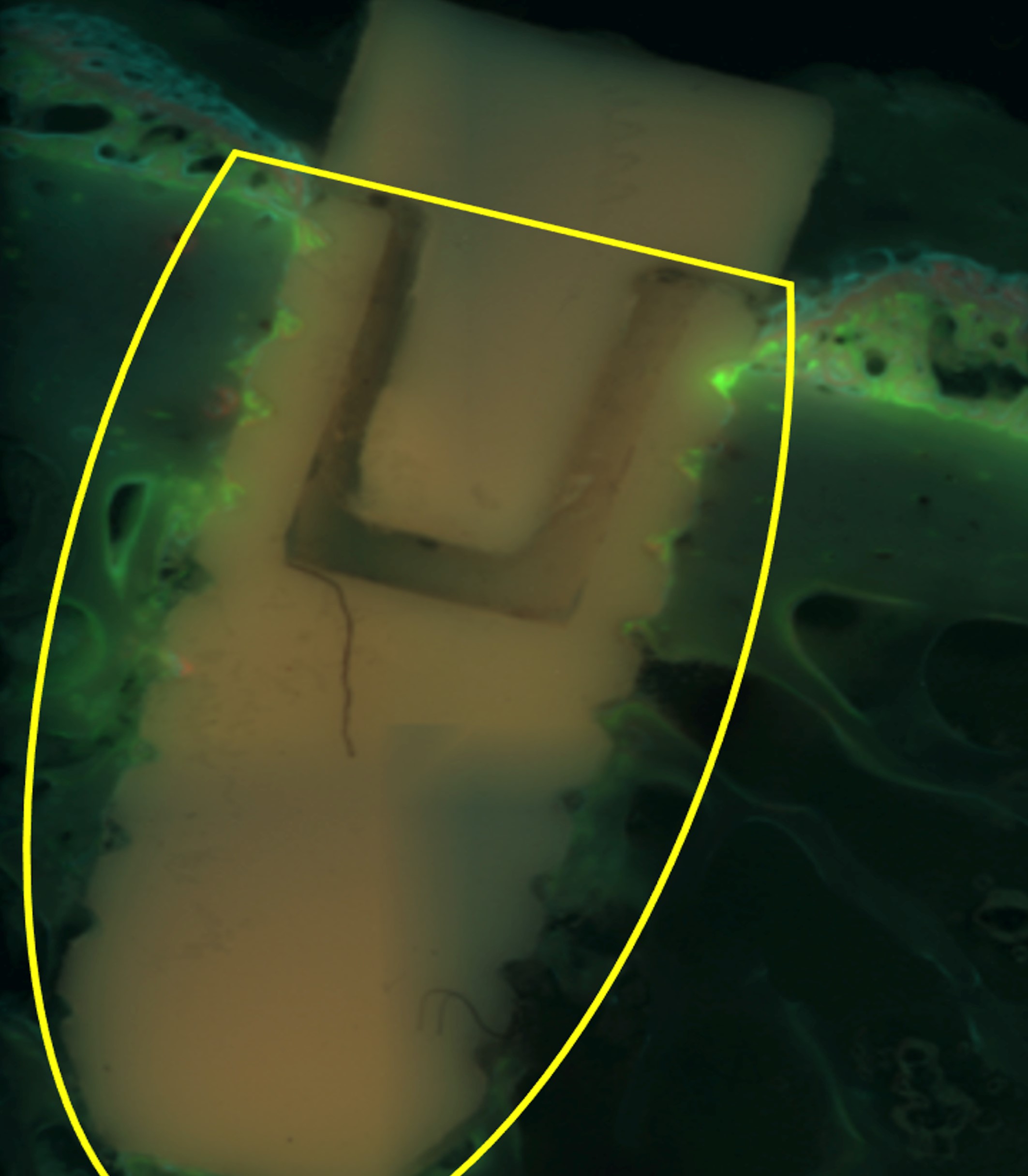

To what extent have you already implemented this transparency strategy at stimOS?

We have commissioned our certification body, QS International, to carry out a pilot test to evaluate our MBT (Mimicking Bone Technology) surface technology according to the S.P.E.L. matrix. But although we have researched and worked according to the required methods, we will probably not achieve a 100 percent evidence level either. This is because part of this work has been carried out in an ‘experimental’ environment with universities. In addition, we are currently compiling a compendium that we will make available on our website.

Can other companies now have their implants certified in order to obtain a quality seal?

We will also introduce the S.P.E.L standard to other certification bodies. At the moment, however, any interested manufacturer can contact QS International AG. One of the desirable outcomes would be the quality seal attracting the attention of decision-makers such as purchasers or health insurance companies.

Can the assessment procedure also be transferred to other medical devices?

Yes, absolutely. The questions and the categories are slightly different, but the common thread remains the same: How was the device developed, and is the test based on real conditions? For example, we have adapted the evaluation matrix for 3D-printed mechanical implants in a second position paper. Here, such a transparency strategy might be even more important than for surface functionalisations, because 3D-printed implants are often individually tailored to the patient. Therefore, they are usually not subject to the complete CE assessment procedure. In my opinion, the S.P.E.L. matrix can be applied to many different medical devices. We are currently thinking about a software evaluation matrix.

From May 2021, the new European Medical Device Regulation (MDR) will apply. Will it lead to more quality and transparency in medical devices?

It does not change the fact that the CE mark does not enable any conclusion to be made as to how the test results of the implant components were obtained. The requirements for a medical device are simply enforced and checked more consistently. The transparency that we are calling for as an accompanying voluntary documentation will be just as meaningful under the new MDR.

References:

1) Schaffarczyk, D. et al.: Polyetherketone implant surface functionalization technologies and the need for a transparent quality evaluation system. Polymer International Dec. 2020. DOI: https://doi.org/10.1002/pi.6162

2) Schaffarczyk, D. et al.: Applying S.P.E.L. (safety and performance evidence level) standard to patient matched medical devices: The need for a transparent regulatory matrix to qualify new manufacturing methods and technologies. MedDEV Quarterly News 2021; Q1: 23-29. https://fliphtml5.com/ymtgz/zagd; DOI: 10.5281/zenodo.4541811